CC®-505 Case Study

CC®-505 cycling a 2 litre Radleys jacketed reactor

Requirement

This case study demonstrates the ability of the CC-505 refrigeration bath circulator to cycle the process temperature in a range from +20°C to -50°C, the closeness of the temperature control and the minimum process temperature achievable in the process mass.

Method

The 2 litre Radleys reactor was connected to the CC-505 using two M24x1.5 1-meter flexible hoses. The thermofluid used in the system was M40.165.10. “Process” control was carried out via a Pt100 sensor located in the process mass. Stirrer speed was set to 200 rpm.

Setup details

>`` Temperature range: -50°C...+200°C``

>- `Cooling power: 1.2 kW @ +100°C`

>-1.2 kW @ +20°C

>-1.0 kW @ 0°C

>-0.6 kW @ -20°C

>-0.15 kW @ -40°C

>-Heating power: 1.5 kW

>-Hoses: M24x1.5; 2* 1 m

>-HTF: M40.165.10

>-Reactor: Radleys 2 litre

>-jacketed reactor

>-Reactor content: 1.5 litre M40.165.10

>-Stirrer speed: 200 rpm

> ``Control: process ``

Results

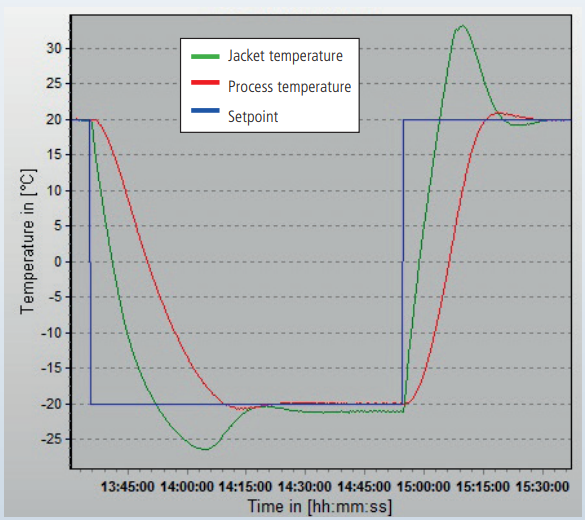

Performance:

Cooling down and heating up in a range from +20°C to -20°C.The CC-505 needs approximately 45 minutes to cool down the reactor from +20°C to -20°C and 35 minutes to heat it up from -20°C to +20°C.

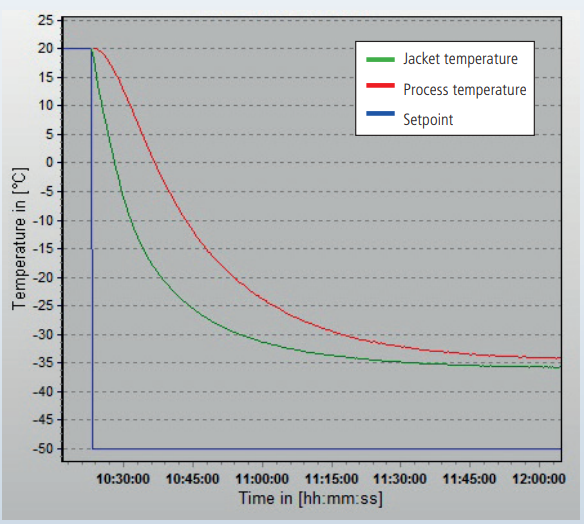

Lowest achievable temperature (Tmin):

Once stable at +20°C under “Process“ control, a set-point of -50°C is entered. The CC-505 cools the reactor down to the minimum achievable process temperature of -34°C.